Full servo baby diaper making machine NK550-SV

PARAMETER OF EQUIPMENT FUNCTION

◎Designed speed: 240m/min

◎Working speed: 550pcs/min(Small size)

◎Qualified rate: 97% (The rate is compared with qualified products with gross output products within7.5 hours)

◎Efficiency: ≥85%(The rate is compared real output with principle output within 7.5 hours)

◎Installed capacity: 280KW (Including hot melt system)

◎practical capacity: 200KW(Including hot melt system)

◎Electric power supply: Three-phase & four-wire 380V/50HZ(Ground wire)

◎Electric wire: 3x120mm2+1x50mm2+1x25mm2

◎Lowest barometric pressure: 8kg/cm2

◎Air compressor: >0.6Mpa, 1.8m3/min, 22kw(to be reference)

◎Gross weight: 70000kg

◎Noise: <85dB(A)

◎Machine size: (32x8x3.5)M

◎Working size: (38x12x4)M

◎Color: Silver (According to order)

◎Range of products: Five Sizes ( XXL、XL、L、M、S)

◎Length of products(mm): 580(XXL)、540(XL)、500(L)、450(M)、390(S)

◎Container: 4x40HQ+1x20GP

Full servo adult diaper making machine LKC-SV

PARAMETER OF EQUIPMENT FUNCTION

◎Designed speed: 240m/min

◎Working speed: 200pcs/min(M size)

◎Qualified rate: 97% (The rate is compared with qualified products with gross output products within7.5 hours)

◎Efficiency: ≥85%(The rate is compared real output with principle output within 7.5 hours)

◎Installed capacity: 400KW (Including hot melt system)

◎practical capacity: 340KW(Including hot melt system) Breaker Capacity: 600A

◎Electric power supply: Three-phase & four-wire 380V/50HZ(Ground wire)

◎Electric wire: 3x120mm2+1x50mm2+1x25mm2

◎Lowest barometric pressure: 8 kg/cm2

◎Air compressor: >0.6Mpa, 1.8m3/min, 22kw(to be reference)

◎Gross weight: 75000kg

◎Noise: <85dB(A)

◎Machine size: (31×9x3.5)m

◎Working space: (35x13x4)m

◎Color: Silver(According to order)

◎Range of products: XL、L、M、S

◎Container: 4×40HQ+1×20GP

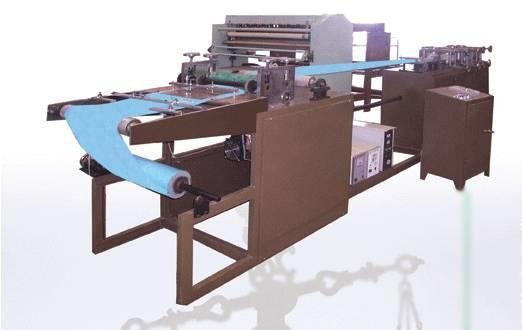

Snitary napkin production line/lady napkin productin line

Main functions and features

◎Driving way: shaft rotation (this machine adopts frequency conversion motor, gear bo×, universal shaft, synchronous belt in transmission)

◎It can produce ultra-thin or fluffy pulp cotton core type sanitary napkin, which is fast-easy package.

◎It adopt PLC+Touchable screen+ frequency control system

◎Main raw materials automatic splicing device

◎Main raw materials tension control device

◎Main raw materials PE film web guide system

◎Main raw materials unqualified parts will remove automatically.

◎Production of automatic shutdown system failure.

◎Cutter material use 45 # steel, e×tend life of the cutter.

◎Higher speed crusher machine can crush treated or untreated fluff pulp.

◎Touchable Screen: Motor switch on/off, running speed, time, countting pieces, parameter setting, alarm, error display,error enquiry (functions setting appear on screen are different according to different machine type)

◎Machine with safty door

Main technical parameters

◎Designed speed: 140m/min

◎Running speed: 350-400pcs/min

◎Product Size: Single type (product lengh can according to customers’ require)

◎Capacity: 140kw 380V, 50 HZ (Including glue Applicators)

◎Practical capacit: 100kw Breaker: 400A

◎Electricity: 3phases 4 lines 3x70mm2+1x50mm2+1x25mm2

◎The lowest air pressure: ≥0.6mpa, 1.3m3/min

◎Total weight: about 35Tons

◎Noise: <80db (A)

◎Main machine overall dimensions: (22x5x3)M(LxWxH)

◎Machine taking total space: (26x9x4)M(LxWxH)

◎Container: 2x40HQ

Under pads production line/pet pad productin line

Functions and Features

◎Reasonable structure and refined parts make it reliable when being used and the assemblage function makes the transportation and installation much easier.

◎It is controlled under the heavy-current or industry computer. It is easier to operate and adjust.

◎During the process of operation, the quantity of velvet laid for the core can be under non-step adjustment and the combine roller can be used to ensure appropriate thickness of the core. Besides, wastes of fluff pulp can also be recycled and re-feeding.

◎All the products are fully embossed, making them bright and good-looking.

◎Machine can produce products of different sizes. Release paper can be added to the back sheet as optional .

◎Tissue paper, air-laid paper and fluff pulp can be used to produce under pads.

◎SAP can be supplied at a fixed amount in designed locations or in a fixed position.

Option Device

The length of products can be realized through frequency adjustment without stopping and changing any spare parts, so as to reduce the wastage rate and increase the work efficiency.

Main Technical Parameters

◎Model: JWC-CFD

◎Designed speed: 100 M/Min

◎Real production Speed: 80 M/Min

◎Product size: L: (350-1500)mmxW(300-900)mm

◎Electricity: 380V 50HZ,

Cable: (3x50mm2+1x25mm2+1x10mm2)

◎Air compressor: ≥0.6mpa ,1.2m3/min

◎Installation Capacity: 100kw(including glue applicators)

◎Real running capacity: 80KW .Breaker: 250A

◎Machine size(without crusher): (20x4x3)M(LxWxH)

◎Machine operation area: (24x8x4)M(LxWxH)

◎Weight: 20T

◎Container: 2x40HQ