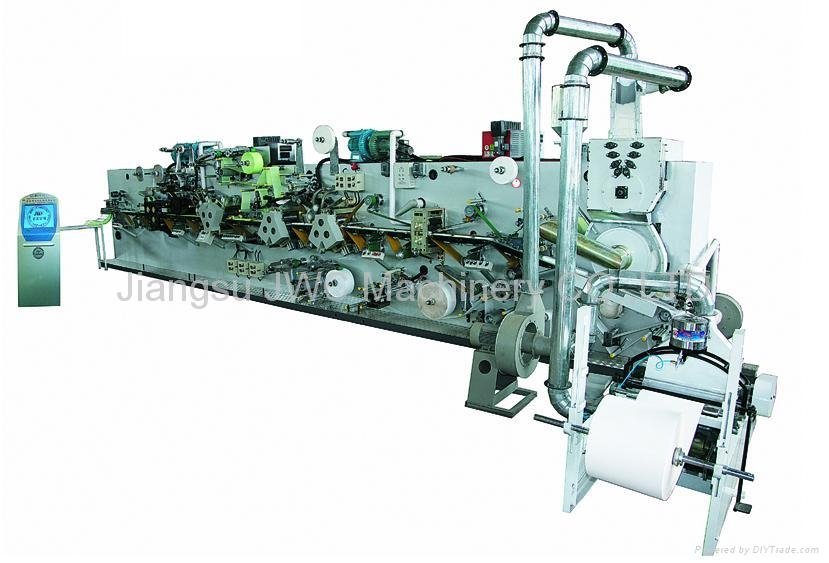

WET WIPES PRODUCE LINE 5-30pcs/bag

Flowing chart: auto unwind -→length ways folding -→quantitative moisture -→cutting-→traverse folding -→transport -→auto packing -→auto date printing-→air press -→hot end seal and cut-→finished product output

1-1 UNWIND

1) Raw material: dust-less paper, spunlace non-woven

2) Raw material width: 14

3) Raw material weight:35

4) Raw material out diameter:

5) Raw material inner diameter:

6) Photocell check, when the raw material is used up, the machine atop automatically

1-2 FOLDING

1) Folding width: 50

2) Folding type: V, Z, W… adjustable

3) Cut length:

4) Wet wipes width:

5)Folding speed: 550-600pcs/min

6) Operation panel: 4.2〞liquid screen

7) Moisture type: quantify moisture is supplied in the fix amount

8)Counting ways: electronic counting, LCD panel write.

9)Splitting type: stainless steel round plate cutter

1-3 RECIPROCATING PACKING MACHINE

1) Bag length:120

2) Packing width:50

3) End seal type:flate or zig-zag for your choice

7) Temperature control: 0

8) Speed control:0-80 bags/min

9) Operate inter Face:10.4〞liquid screen

..........................

15) Gas requirement:0.5-0.8Mpa,0.01㎡/min

16) Power requirement:380vAC 50Hz 8KW

1-4 TRANSPORT

1)Valid transport Length:

2) Material: SUS 304

3) Flat board: SUS 304 diamond plate

4) Working width: 50

1-5 MIX TANK

1)Volume:

2)Material: SUS 304

3)Mixed motor: 1HP 380vAC 50Hz

4)Supply liquid pump: :0.5HP 220/380vAC 50Hz,1set

5)Liquid filter:80 mesh double filter

7) Disinfect connector: reserve /ISO snap ring

8) Disinfect type: steam pressure≤0.48kgf/cm² & ≤+

1-6 AUTOMATIC GRINDING MACHINE

1) Driving motor: 1 HP 380vAC 50HZ

2) Grinding ways: batch (-type) pneumatic

Sanitary napkin machinery- auto shifting

Main functions features:

1. It has got national patent in the year of 2005. 2. It adopts double-knives, double-moulds, and double-embossing.

3. The machine can produce two sizes sanitary napkins of regular type, ultra-thin type wings type.

4. Pushing the shifting button will move the gears and shaft so that the specification can be changed within the shortest time

5. It can adopt PLC controller system. Alarm and urgent stop machine .can be settled according to the customers requirements.

6. Crone gears are protected by cast shield box and greased to maintain precision, less noise and long life.

2、Main Technician Parameters:

1. Type: HYHD

2.Overall Dimensions:14m*2.7m*3m(L*W*H)

3.Working space:15m*4m*4m(L*W*H)

4.Total weight:10.5T

5.Power supply:380V 50Hz

6.Installation capacity:44KW

7.Air consumption:1000 Liters/min,8-10 Bars

8.Designing output:300pieces/min

9.Equipment output:150-250 pieces/min

10.Equipment specification:225-340mm

High speed crusher

Function and Features:

1. Adopt imported high accuracy & heavy load bearing

2. Adopt step less speed regulation feeding electrical motor, it can directly linkage main machine for feeding.

3. Adopt wear-resisting tooth piece for crush raw pulp and may the double-decked feeding crushing.

4.Set the cotton wastage recovery port

5. The Crusher can make the length and effect fitable.

6. The fixed crushing amount is 300-350kg/h

7. The max width of raw materials is 520mm.

Diaper Stacker JWC-DDJ-600

Fuctions and Features

Full servo driven system . It can be attached to use with high-speed or full servo baby diaper machine .

Auto detecting system

Touch screen control panel , control with picture .

Compact designed , easier for operation

It can pack diapers in different quan

Table napkin folding machine

Main Technical Parameters

Machine model |

CJ4-6? |

|

| Finished Products Size (mm) |

200×200mm(Other sizes are available) |

|

| Machine Width (mm) |

800~1200 |

|

| Raw Material Diameter (mm) |

Φ1100 mm (Other sizes are available ) |

|

| Raw Material Core Diameter (mm) |

76 mm (Other sizes are available) |

|

| Speed |

3800-5000 sheets /min |

|

| Programmer Controller |

PLC Programmable Controller |

|

| Embossing Unit |

Steel to rubber embossing, steel to steel embossing |

|

| Bottom Embossing Roller |

Felt roller, Paper roller, Rubber roller |

|

| Calendaring |

Steel to steel, steel to rubber |

|

| Edge Embossing |

Steel to steel, independent adjustment |

|

| Jumbo roll guiding system |

Optional |

|

| Slitting unit |

Pneumatic dot slitting |

|

| Lubricating system |

Key parts regularly lubricating automatically. |

|

| Driving system |

Timing belt driving system |

|

| Counting system |

Alternate stack by stack |

|

| Main Motor Power |

Frequency converter to control the speed 5.5-11KW |

|

| Air Pump Power |

11-32KW |

|

| Pneumatic System |

3 HP air compressor, mini pressure 5kg/cm2 Pa |

|

| Dimension |

5250×1800×2000 |

|

| Weight |

6200-8500kg |

|

| Optional device |

||

| Programmer Controller |

Programmable Controller (PLC), LCD touch button |

|

| Power? |

Variable frequency |

|

| Driving system |

Timing belt, chain |

|

| Embossing Unit |

Steel to rubber embossing, steel to steel embossing |

|

| Bottom Embossing Roller |

Felt roller, Paper roller, Rubber roller |

|

| Slitting unit |

Pneumatic dot slitting |

|

| Edge Embossing |

Steel to steel, independent adjustment |

|

| Calendaring |

Steel to steel, steel to rubber |

|

| Pneumatic System |

Roots vacuum pump |

|

Four sides sealing wet napkin making machinery

SPECIFICATION :

Suitable materials:dustless paper,nonwoven fabrics

Raw Material :25g/m2-80g/m2

Fold Width : 76-115 mm(adjustable)

Cutting Length : 100-300 (digital adjustable)

Splitting Width : 150-305mm (per sheet)

Capacity : 2000-4000 sheets/min or 25-80 bags/min

Splitting device : Double line 12 channel ( Jumbo Roll

width 600-1500mm)

Counter :Automatic / set pile.

Fold Type : Continue type or V,Z,C fold type.

Moisture : 100%-400% (adjustable)

Water storage : 2 sets of 600 Ls stainless mixer tank.

Power : Ac 380V., 50/60Hz., 15KW

Machine Size : 15500(L) 3500(W) 2500(H)mm

Machine Weight : NW.8000 KGS

Flowing Chart : Raw Material-Splitting-Folding-

Moisture-Pile-Transport-Filling-Film

Hole making-Sticker set-Wrapping-

Finishing